Shop

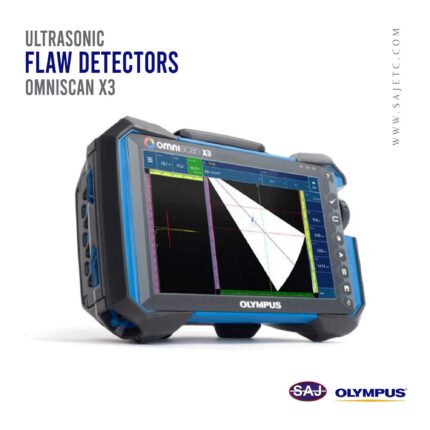

OmniScan™ X3

Each flaw detector in the OmniScan™ X3 series is a comprehensive phased array solution. Equipped with cutting-edge Total Focusing Method (TFM) and advanced Phased Array (PA) features, it ensures precise flaw detection with confidence. User-friendly software and streamlined workflows enhance efficiency, helping you achieve greater productivity.

OmniScan™ SX

The compact and lightweight OmniScan™ SX flaw detector is designed for efficiency and ease of use, featuring a bright, easy-to-read 8.4-inch (21.3 cm) touchscreen display. Offering cost-effective inspection solutions, the OmniScan™ SX is available in two models: the SX PA and SX UT. The SX PA model is a 16:64PR unit equipped with a conventional UT channel, ideal for phased array (P/E), pulse-echo (P-C), and time-of-flight diffraction (TOFD) inspections. Similarly, the SX UT model is optimized for conventional UT inspections, ensuring versatile and reliable performance in a wide range of applications.

EPOCH 650

The EPOCH 650 is a versatile ultrasonic flaw detector that delivers exceptional inspection performance across a wide range of applications. Built for ease of use and durability, this advanced instrument builds on the success of the popular EPOCH 600, offering enhanced capabilities for even greater reliability and precision in flaw detection.

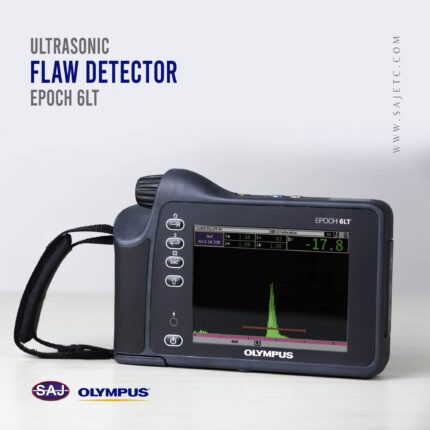

EPOCH 6LT

The EPOCH 6LT is a lightweight, portable ultrasonic flaw detector designed for one-handed use, making it ideal for rope access and other high-mobility applications. Its ergonomic design ensures a comfortable fit in hand or can be securely strapped to the leg, offering convenience and flexibility during inspections in challenging environments. With reliable performance, the EPOCH 6LT is optimized for efficient flaw detection on the go.

U-Visc kinematic viscometer

The U-Visc viscometry system is engineered to fully comply with ASTM D445 standards, offering low solvent consumption, high unattended throughput, and exceptional ease of use—all with reliable performance. Available with single or dual solvent cleaning, this tailor-made instrument measures kinematic viscosity in Newtonian fluids like lubricants, fuels, or dissolved plastics between 0.15 and 25,000 mm2/s.

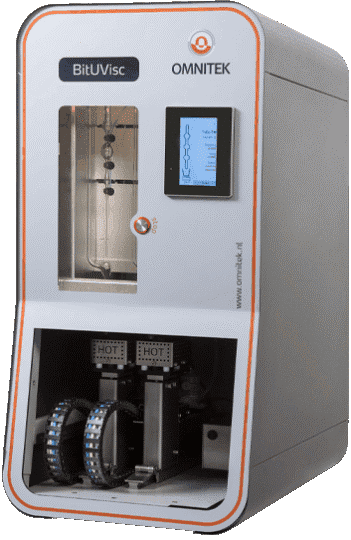

BitUVisc kinematic viscometer

Introducing a revolutionary instrument that eliminates the hassle of manual loading, measuring, and cleaning of high viscosity samples—making your process faster and more efficient. Fully automatic viscometer for highly viscous samples up to 120,000 mm²/s.

MiniVisc 3000 – Portable Kinematic Viscometer

Introducing the New ASTM D8092 Standard for Direct Kinematic Viscosity Measurement. The MiniVisc 3000 Series is a portable, temperature-controlled kinematic viscometer, designed to meet the latest ASTM D8092 standards for accurate and reliable viscosity measurements on the go.

SpectrOil 100 Series – (RDE-OES) Elemental Analyzer

The SpectrOil 100 Series is a precision benchtop RDE-OES elemental analyzer for lubricants, fuels, coolants, and water. As the eighth generation of the market-leading RDE spectrometer, it provides accurate elemental analysis for use in commercial oil labs, on-site, or in mobile labs.

LaserNet 200 Series – Automated Wear Debris Analyzer

The LaserNet 200 Series is a contamination and wear debris analyzer for monitoring lubricant condition in predictive maintenance. It provides fast, accurate assessments of machinery health using just a few milliliters of fluid, helping users detect wear modes, particulate contamination, filtration efficiency, and changes in ferrous debris concentration.

FluidScan 1000 Series – Handheld Infrared Oil Analyzer

The FluidScan® 1000 Series is a handheld infrared analyzer that monitors lubricant and grease condition. It provides direct measurements of oil quality, enabling proactive maintenance decisions by detecting chemical degradation or contamination. Compliant with ASTM D7889, it’s essential for effective machine condition monitoring.

FDM 6000 – Portable Fuel Dilution Meter

The FDM 6000 Series is a portable, battery-operated fuel dilution meter that quickly measures fuel dilution in engine oil. Its unique fang design pierces a sample vial cap and draws in headspace, which flows over a Surface Acoustic Wave (SAW) sensor that detects fuel vapor at concentrations of 0–15%. Capable of identifying diesel, gasoline, or jet fuel, it conforms to ASTM D8004, the standard test method for fuel dilution in in-service lubricants.